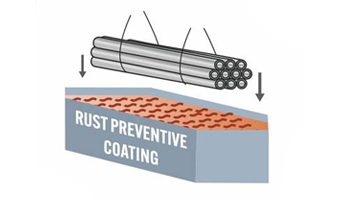

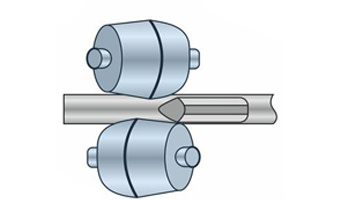

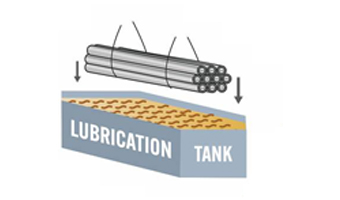

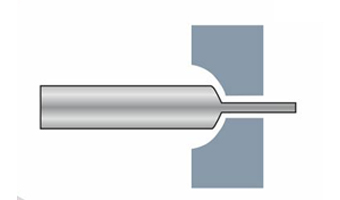

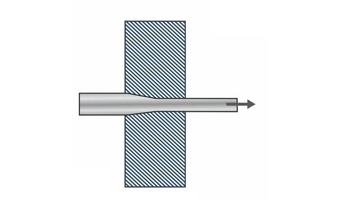

Our Manufacturing Process

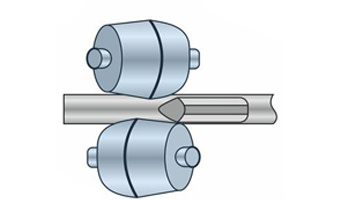

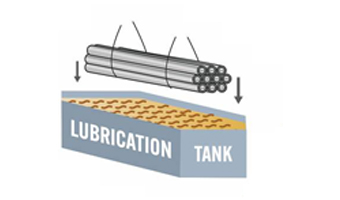

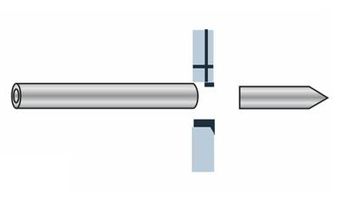

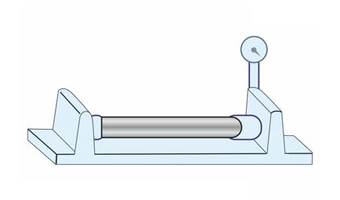

The Art and Science of Shaping Raw Steel into Exceptional Pipes.

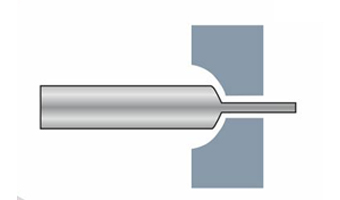

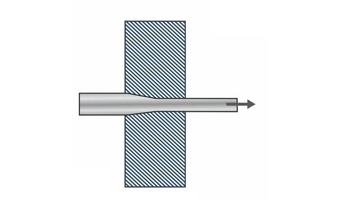

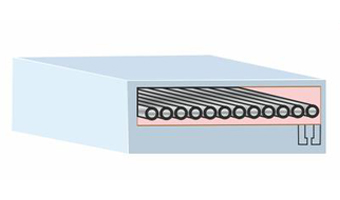

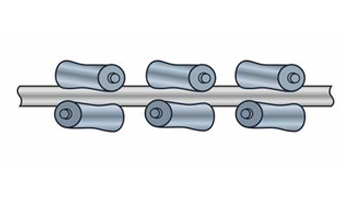

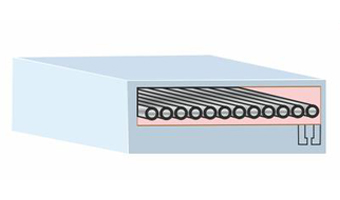

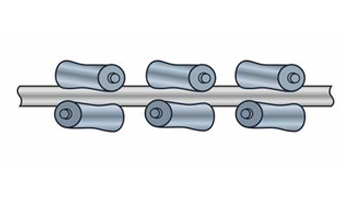

Manufacturer & Exporter of Carbon and Alloy Steel Seamless Tubes & Pipes and Fin Tubes

The Art and Science of Shaping Raw Steel into Exceptional Pipes.