Inspection And Testing

Every tube we produce undergoes rigorous inspection and testing to ensure it meets international standards. From mechanical to chemical testing, our in-house quality checks guarantee reliability and performance. Contact us to learn more about our testing protocols or request detailed reports.

1. Dimension Check :

Ensure dimensional accuracy Of OD, ID, Thickness, Length, Ovality etc.

2. Surface Check :

To ensure that finished tubes are free from scale,pit marks rupture I.D. & O.D score,roll markes,dent etc.

3. Chemical Test :

To test chemical constituents & quelity parameters of raw material & finished product.

4. Mechanical Test :

Hardness Test :

To test hardness of the tubes. It is carried out by Rockwell / Twin hardness testers.( HRC, BHN Scale ).

4. Mechanical Test :

Tensile Test :

To check the tensile strength of the tubes

4. Mechanical Test :

Flaring Test :

To check the ductility of material.End of tubes should be flared successfully without developing cracks.

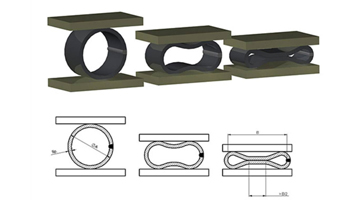

4. Mechanical Test :

Flattening Test :

This test is conducted to check the strength by subjecting to extreme compression stress.

4. Mechanical Test :

Flange Test :

The photo besides shows a test piece subject to Flange Test as per standard.

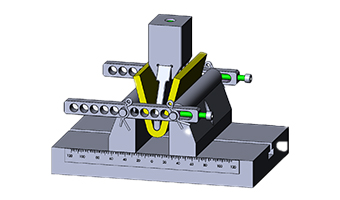

4. Mechanical Test :

Bend Test :

Pipes are bent as per specification at 90 C. without developing cracks.

5. Non Destructive Test :

Hydro Test (Uo to 1500 Bar) :

To check that there should not be any leakage, 100% Hydrosatic testing is carried by precision machine on all tubes.

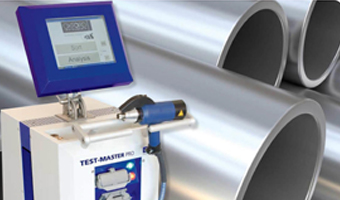

5. Non Destructive Test :

Eddy Current Test :

To detect subsurface inhomogeneities from inside & outside of tubes.

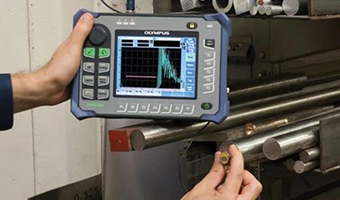

5. Non Destructive Test :

Utrasinic Test :

For detection od subsurface flaws & imperfection

5. Non Destructive Test :

Air Under Water(PNEUMATIC) :

This test is carried out on request. It is carried out by immersing the tubes in water under compressed air to determine minior leakages.